| Operating Voltage | 90~260VAC-50/60Hz |

| Power Consumption (Watts) | 35 |

| Output Type | 2Relay-8A-250V-SPDT |

| Operating Temperature (Celsius) | -20 to +60 |

| Conveyor Speed (Meters/Second) | 0.1 to 4.5 |

| Conveyor Chassis Width (Centimeters) | 95 to 135 |

| Coil Opening Height | 8 to 62 |

| Coil Material | PE+ABS |

| Control Box Protection Rating | IP65 |

| Smallest Detectable Metal Piece | 5 cm diameter iron ball |

| Coil Dimensions (WxDxH) Centimeters | 150x33x100 |

| Coil Weight (Kilograms) | 55 |

| Control Box Dimensions (WxDxH) Centimeters | 54x25x50 |

| Control Box Weight (Kilograms) | 25 |

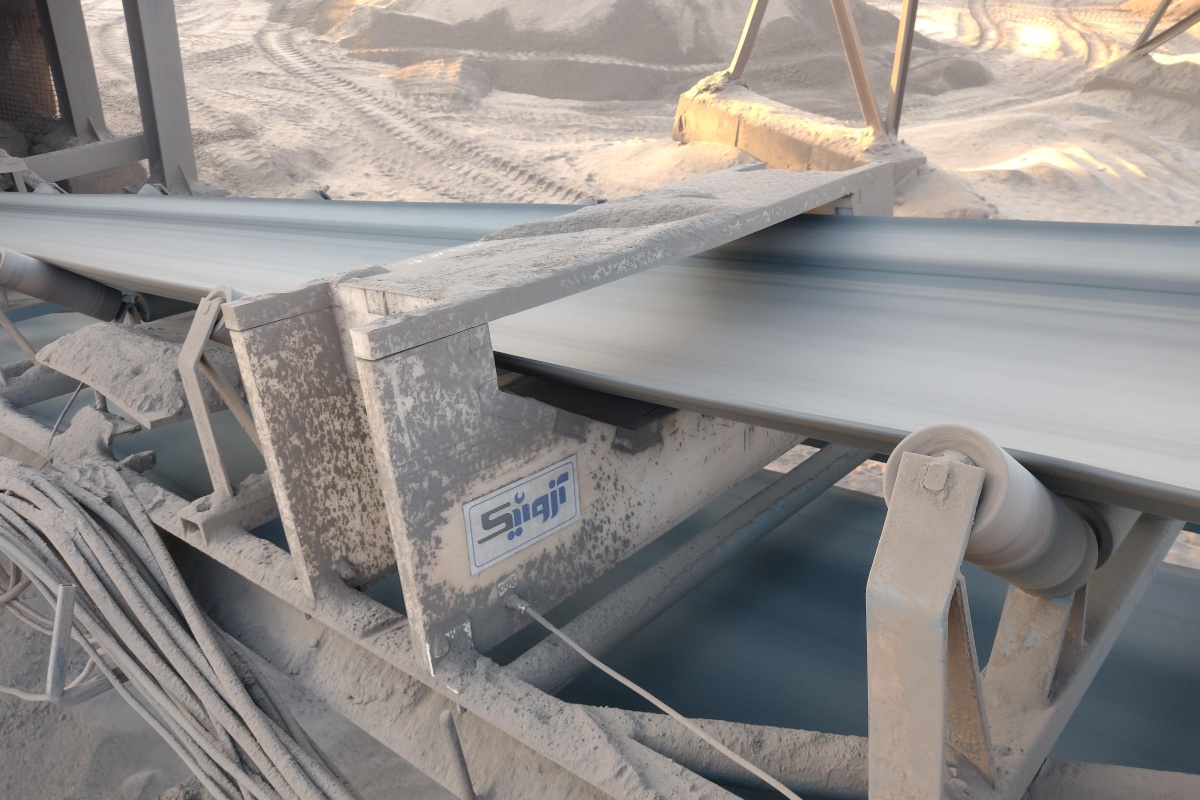

Conveyors transport input and output materials of various devices and machines in mines. Waste and debris on the conveyor pose risks to the performance of this mineral processing equipment. Examples include metal pieces from mechanical excavators, loader claws, worn iron sheets from machinery, etc. These metallic wastes typically cause wear, damage, or complete line stoppage.

The conveyor metal detection device detects these metallic wastes and stops the conveyor line to prevent damage to subsequent equipment such as hydrocone crushers and stone crushers.

The Azonic conveyor metal detection device, with an advanced proportional processing and control system, adapts its performance based on the type and size of iron ore pieces on the conveyor, ensuring that changes in ore type or size do not cause detection errors. Measurement accuracy and conveyor speed settings are easily adjustable via control knobs on the device’s control board. The device has two programmable relay outputs for connection to the conveyor control and monitoring system.

Features and Applications:

- Use in iron ore conveyor lines

- Automatic line adaptation system

- Device sensitivity adjustment

- Conveyor speed adjustment

- Two programmable relays