Our Latest Products

Technology Localization

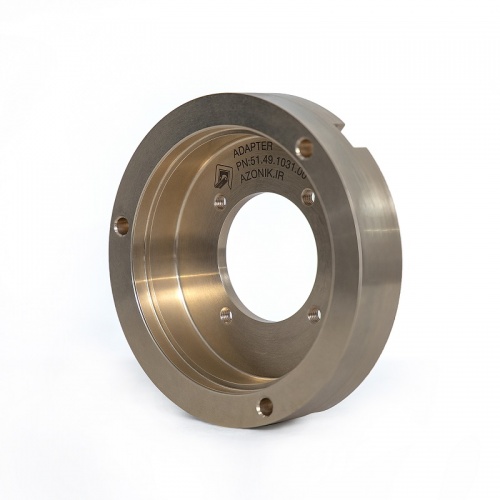

Speed Sensor

Industrial Metal Detectors

Universal Tensile and Compression Machine

Test Equipment

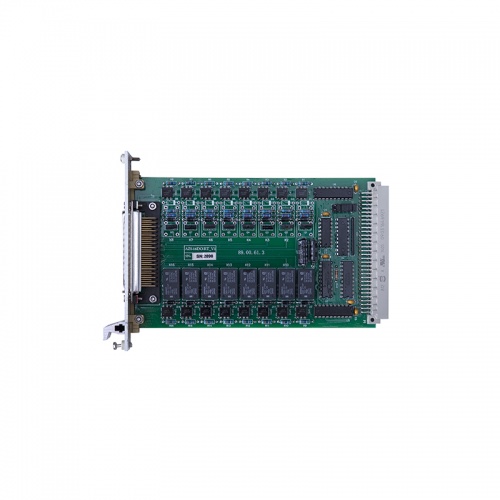

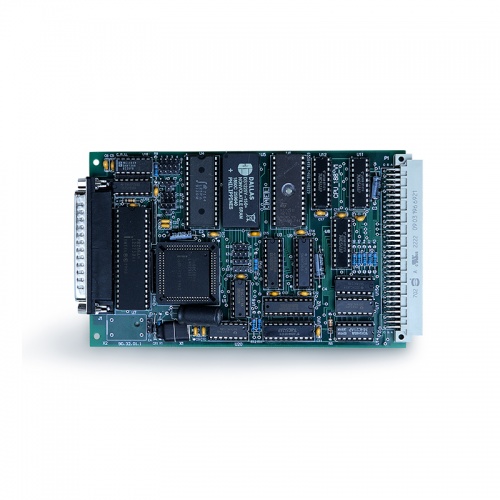

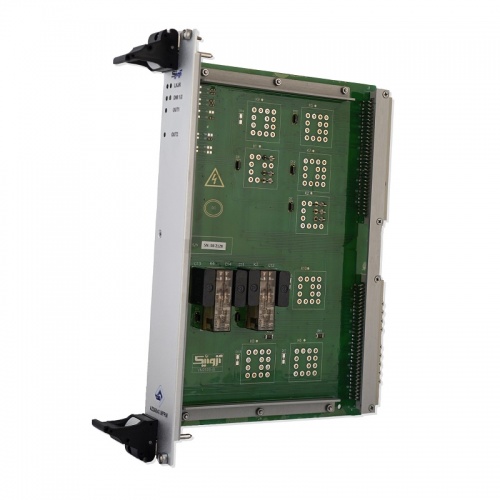

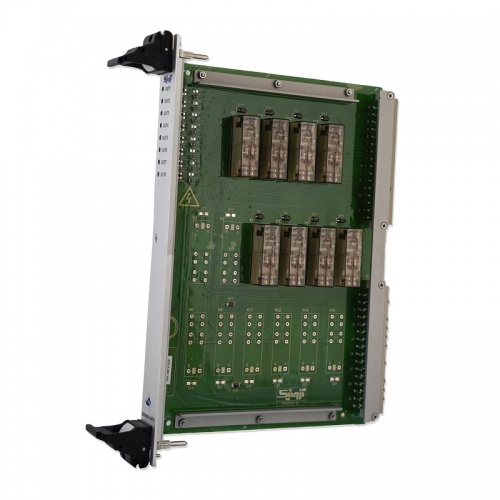

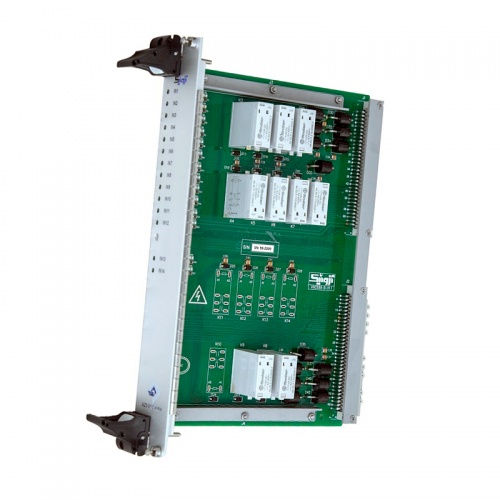

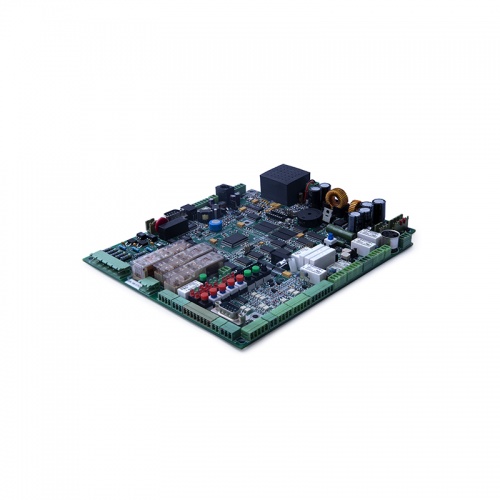

Reverse Engineering of Electronic Boards at Azonik

At Azonik, reverse engineering services for electronic boards are provided using local technical expertise and extensive industrial experience. These services are particularly crucial when imported or obsolete equipment is no longer available, and a reliable and stable replacement is needed. Our expert team, utilizing advanced equipment, carries out the redesign and production process of boards, from analysis and schematic extraction to PCB design, assembly, performance testing, and component sourcing, entirely in-house without external dependency. The capability to design and manufacture boards up to 10 layers, combined with reverse engineering at both hardware and software (Firmware) levels, enables the reconstruction and reproduction of various industrial and laboratory boards, even if they are discontinued. In this process, high-precision modeling and full compliance with performance standards ensure that the new sample not only replaces the original but also improves in stability and quality. All stages at Azonik are performed entirely locally. This not only prevents currency outflow but also reduces costs, accelerates supply, and provides sustainable after-sales service. As a result, customers can confidently recover critical electronic equipment and benefit from ongoing local support.

Precision, Reliability, and Innovation in the Product

Speed sensors produced by Azonik are the result of years of experience and expertise in the design and manufacture of advanced industrial equipment. These sensors are designed using cutting-edge technical knowledge and an experienced team to deliver the highest performance even in harsh working conditions. The ability to produce without limitations allows the sensors to be designed and manufactured to meet the specific needs of each project, from general industries to advanced railway and energy projects. Our special focus on the railway industry has ensured that our products are manufactured in compliance with international railway standards (EN50155 and other relevant requirements), providing reliable and stable performance in high-vibration, noisy, and harsh environmental conditions. Features such as high measurement accuracy, strong isolation, resistance to electromagnetic interference, and long lifespan make Azonik sensors a reliable choice for sensitive industries. In addition to superior quality, these sensors offer flexibility in design and full customization, precisely tailored to customer needs. Our successful experience collaborating with large-scale national projects and major industrial organizations is a testament to the capability and efficiency of our products. Choosing our speed sensors is a choice based on trust, expertise, and consistent quality—a product that not only meets your current needs but also provides a reliable solution for the future.

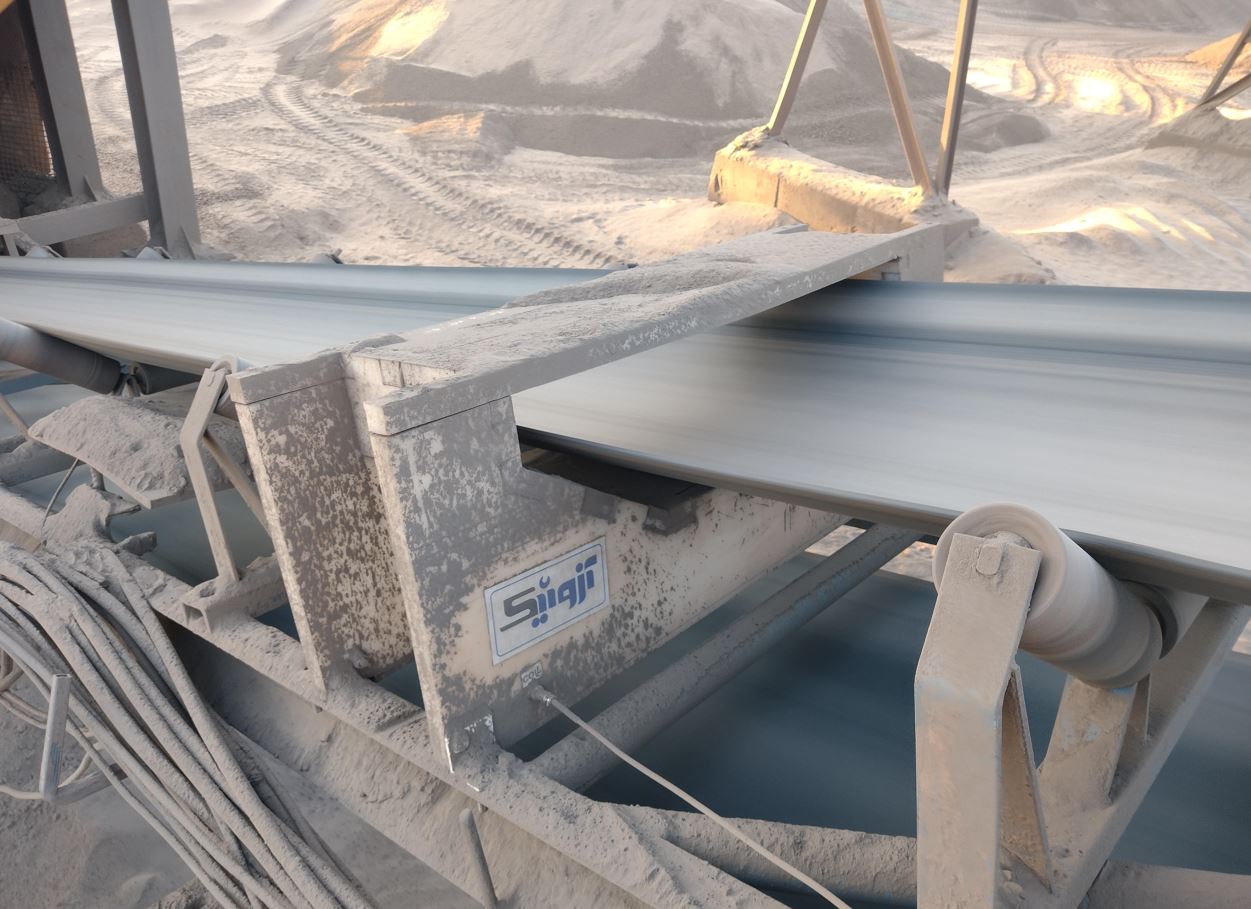

Industrial Metal Detectors

Industrial metal detectors, or metal detectors, have a wide range of applications, from the food industry to mining. These devices are used to monitor the presence or absence of metallic contaminants in input materials or finished products. In the mining industry, raw materials are fed into crushers that break stones into smaller sizes with varying capacities. The input to crushers and hydrocones is supplied via conveyors. While crushers can continuously crush various stones, the presence of metallic objects, such as loader bucket teeth, in the input can cause damage to the crusher jaws or the machine’s shaft. Azonik conveyor metal detectors continuously monitor the input to crushers, detecting any intrusive metallic objects and preventing their passage to the next stage. Azonik conveyor metal detectors are optimized for use in iron ore processing lines and minimize detection errors through Ratio-metric measurement.

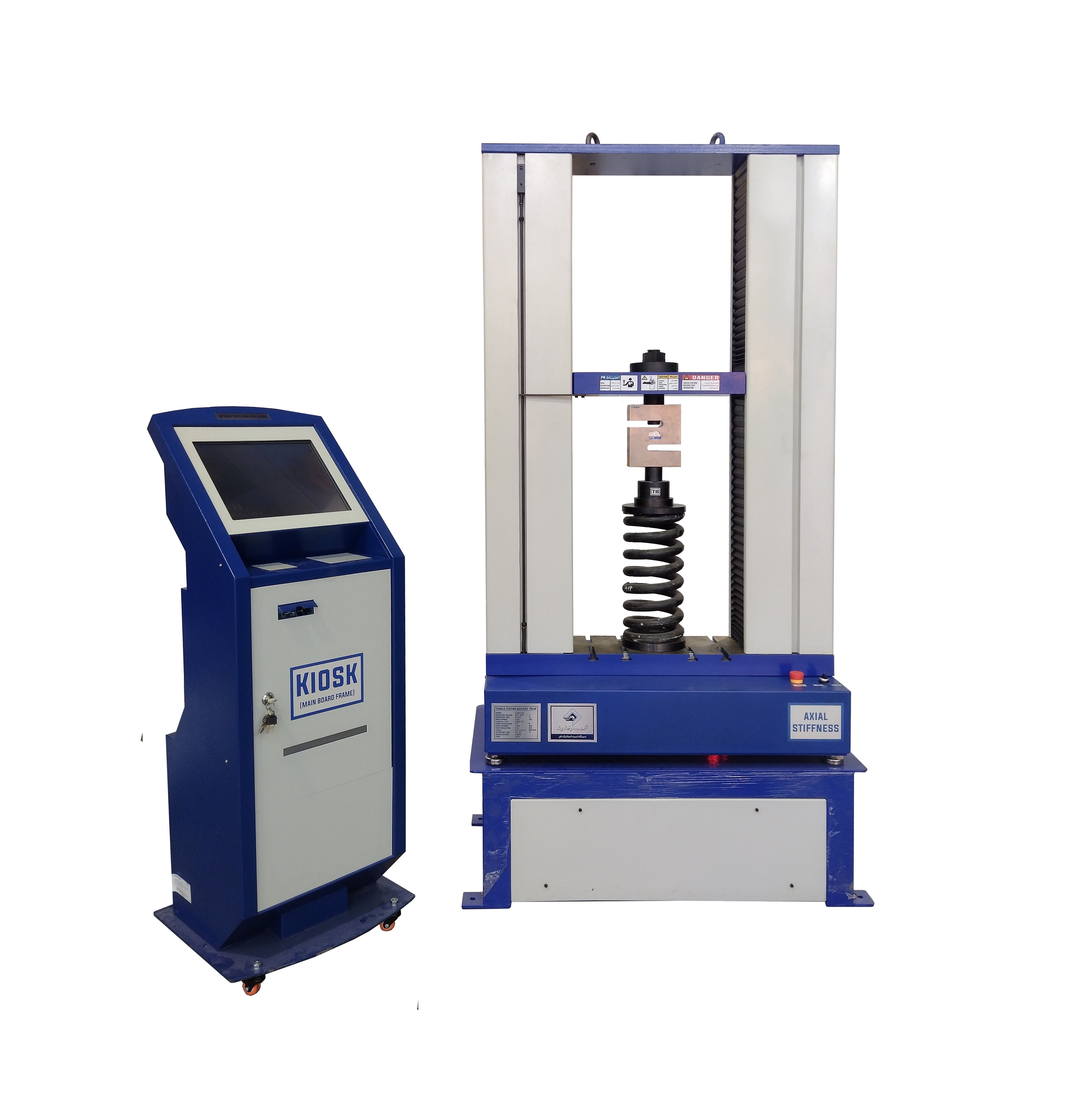

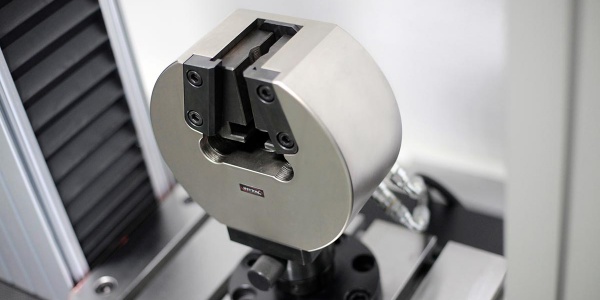

Azonik Universal Tensile and Compression Machine

The Azonik universal tensile and compression machine is a key piece of equipment in materials mechanics laboratories, covering a wide range of industrial and research needs. This machine is produced in various capacities, from 100 kg to over 100 tons, and provides force measurement accuracy at 0.1% of the measured value, delivering fully reliable and standardized results. The measurable elongation range is also tailored to the machine’s capacity, with no design limitations. All hardware and software components of this machine have been developed entirely locally without external dependency. This enables customization of the machine’s mechanical, electronic, and software components to meet customer needs. A robust frame with high coaxial precision and the ability to equip it with various fixtures, extensometers, and ancillary equipment creates ideal conditions for conducting diverse tests. Azonik’s proprietary software, supporting international standards such as ASTM, ISO, DIN, JIS, and Iran’s national standard, allows for the definition and execution of standard and customized tests. This software enables users to plot force-elongation graphs in real-time, create a results database, generate precise reports, and design custom test protocols. From a competitive standpoint, the Azonik tensile machine, in addition to being more cost-effective than foreign counterparts, is a reliable choice for industries and research centers due to local after-sales service, currency savings, and design flexibility. This machine is capable of performing various tensile, compression, bending (two-, three-, and four-point), and other mechanical tests, enabling precise evaluation of the mechanical properties of metallic, polymeric, and composite materials.

Test Equipment

Test equipment is used in scientific, research, and production facilities. The primary purpose of this equipment is the characterization of raw materials or finished products. Test equipment is manufactured in accordance with equipment and calibration standards, such as ISO 7500-1 or INSO 8768-1, and conducts tests based on standards for parts and materials, providing users with the necessary reports. Each type of test requires minimum accuracy and specific measurement ranges. For example, in strength or tensile tests of soft rubber materials, significant elongation occurs at low forces. However, for metallic materials like cast iron or steel, the situation is entirely different. For rigid materials, the applied force is high, and the sample’s elongation is minimal. In the example above, for soft rubbers (e.g., O-rings), a tensile machine with low force application capacity and high displacement stroke is needed. However, for testing metals, a machine with high force application capacity and low stroke is required. The Azonik test equipment production team, by studying the standards and conditions required for the user’s tests, provides the appropriate device and software.

Electronic Boards

Successful Repair

Number of Customers

Support Specialist

Latest Articles

Azonik’s Technological ApproachSpeed sensors are central to industrial monitoring and control systems. Azonik has developed localized speed sensors for rail, oil & gas, and petrochemical industries. [Continued translation...]

Imagine a high-rise building: every component must withstand heavy loads. Choosing the right steel is critical, and tensile testing ensures its quality. [Continued translation...]

Tensile Testing Machine is a vital tool in materials engineering, used to evaluate the strength and mechanical properties of materials, especially metals, under tensile stress. [Continued translation...]

Rotational Speed Sensors in Rail VehiclesMany subsystems in rail vehicles rely on accurate rotational speed signals for traction, braking, and control systems. Speed sensors are installed on wheels, motors, and gearboxes. [Continued translation...]

News & Events

Azonik’s Participation in the 29th International Oil, Gas, Refining, and Petrochemical Exhibition Relying on its technical knowledge and years of experience in designing and manufacturing specialized industrial and laboratory equipment, Azon...

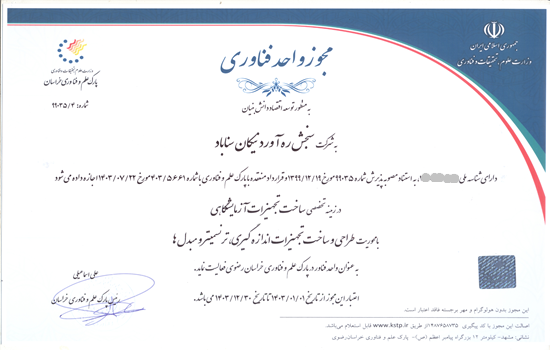

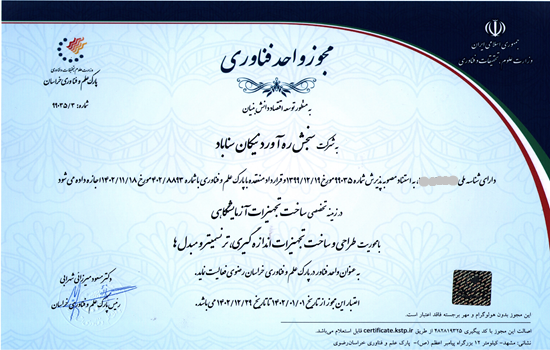

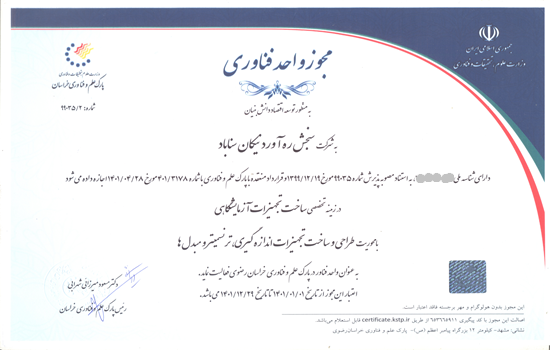

Participation of Sanjesh Rahavard Nikan Sanabad Company in the 12th Iran-Made Exhibition of Laboratory Equipment and Materials Relying on years of experience and expertise in designing and manufacturing specialized laboratory equipment, Sanjesh Ra...

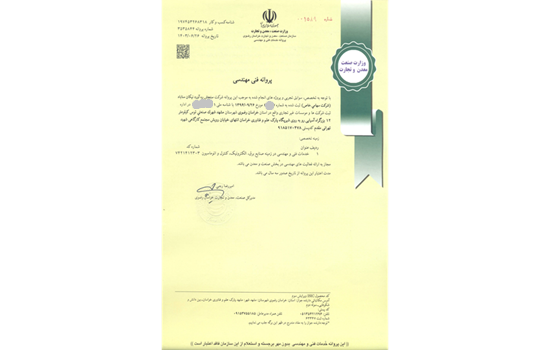

Sanjesh Rahavard Nikan Sanabad Company, through the efforts of its specialists and technical teams, has successfully produced many of the critical components and equipment for the Mashhad Urban Railway that were previously imported from abroad Acc...